In the modern elevator industry, the pursuit of the perfect ride is a relentless challenge. Passengers demand a start and stop so smooth they barely feel the motion, while building owners demand systems that are energy-efficient, safe, and easy to maintain. At the heart of achieving this balance is the synchronization between the Elevator Inverter (VFD) and the Traction Motor.

To achieve high-performance control, particularly with Permanent Magnet Synchronous Motors (PMSM), an inverter cannot operate in blind mode. it requires constant, high-speed feedback regarding the motor's position and velocity. This is the role of the PG (Pulse Generator) Card and the encoder. In this professional deep-dive, we will analyze the two industry titans of encoder technology: the Sin/Cos 1387 and the EnDat 1313, and how the IFIND SD320L series optimizes both.

The Anatomy of Feedback: What is a PG Card?

Before comparing specific models, we must understand the fundamental physics. A PG card is a hardware expansion module for an inverter that translates high-frequency pulses from a motor encoder into digital data that the inverter’s CPU can process.

In a closed-loop system, the inverter uses this data to perform Vector Control. By knowing the exact angle of the rotor, the inverter can apply the precise amount of current to create the required torque. If the feedback is delayed or noisy, the result is vibration, noise, or rollback (where the elevator car slips slightly when the brakes release).

Sin/Cos 1387: The Analog Precision Master

The Sin/Cos 1387 (famously pioneered by Heidenhain) is an incremental encoder that utilizes analog signals. It has been the global standard for gearless elevator motors for decades.

Technical Signal Logic

Unlike standard digital encoders that output square waves (A/B pulses), the 1387 outputs two differential Sine and Cosine waves, usually with an amplitude of 1Vpp.

The magic of the 1387 lies in Interpolation. Because the signals are analog waves rather than on/off pulses, a high-quality inverter like the IFIND SD320L can mathematically divide each wave into thousands of smaller segments. This allows the system to achieve a resolution equivalent to over 1 million pulses per revolution, even if the physical encoder only has 2,048 lines.

Commutation Signals (C & D Channels)

Since the 1387 is an incremental encoder, it forgets its position when the power is turned off. To solve this for PMSM motors, it includes additional C and D tracks (one-period-per-revolution signals). These provide the inverter with a rough absolute position during the first power-up, allowing the drive to identify the magnetic pole position of the motor without requiring the motor to move.

Advantages and Limitations

Pros: Exceptional smoothness, extremely mature technology, and widely compatible with 90% of global gearless motors.

Cons: Highly sensitive to electromagnetic interference (EMI). Because the signals are analog, a poorly shielded cable can introduce noise that the inverter interprets as a speed fluctuation, leading to vibration.

EnDat 1313: The Digital Intelligence Revolution

The EnDat 1313 represents the shift toward digital communication in industrial automation. While the 1387 sends waves, the 1313 sends data packets.

The Absolute Advantage

The 1313 is an Absolute Encoder. This means every single position of the motor shaft has a unique digital address.

Zero Homing: When you turn on an elevator equipped with a 1313 PG card, the inverter immediately knows the exact position of the car. There is no need for a tuning run or commutation alignment every time the system restarts.

Safety and Reliability: In emergency power-off situations, the system retains its position perfectly, which is a massive advantage for rescue operations and high-speed lifts.

The EnDat 2.1/2.2 Protocol

The 1313 uses the EnDat serial protocol. This is a bidirectional communication interface. Not only does the encoder send position data to the SD320L inverter, but the inverter can also read memory from the encoder, such as the motor’s temperature or manufacturer parameters stored inside the encoder itself.

Advantages and Limitations

Pros: Superior noise immunity (digital signals either arrive or they don't; they aren't distorted like analog), simpler wiring (fewer cores needed), and highest possible precision.

Cons: Higher cost of the encoder hardware and the PG card. It also requires a more sophisticated processor in the inverter to handle the serial data stream.

Comparing the Performance in PMSM Applications

Permanent Magnet Synchronous Motors (PMSM) are the standard for modern Green elevators. However, they have one major weakness: they have no slip. They must be perfectly synchronized from the very first millisecond.

Anti-Rollback Performance

The biggest complaint in elevator maintenance is the jerk at the start. When the brake opens, gravity wants to pull the car down. The inverter must apply Pre-torque to hold the car still.

1387 Performance: Highly dependent on the quality of the PG card's analog-to-digital converter (ADC). The IFIND SD320L uses high-precision filters to ensure the 1387 signal is clean, providing excellent anti-rollback.

1313 Performance: Generally superior. Because the position feedback is digital and instantaneous, the torque loop can close faster, often resulting in a zero-perceived-movement start.

High-Speed vs. Low-Speed Stability

At very low speeds (during leveling), the 1387's analog interpolation provides a very soft feel. At very high speeds (4.0m/s or higher), the 1313's digital protocol is more robust against the high-frequency electrical noise generated by the IGBT switching.

Installation, Wiring, and Maintenance: A Technician’s Perspective

As a leading supplier, IFIND knows that a product is only as good as its ease of installation.

Wiring Challenges

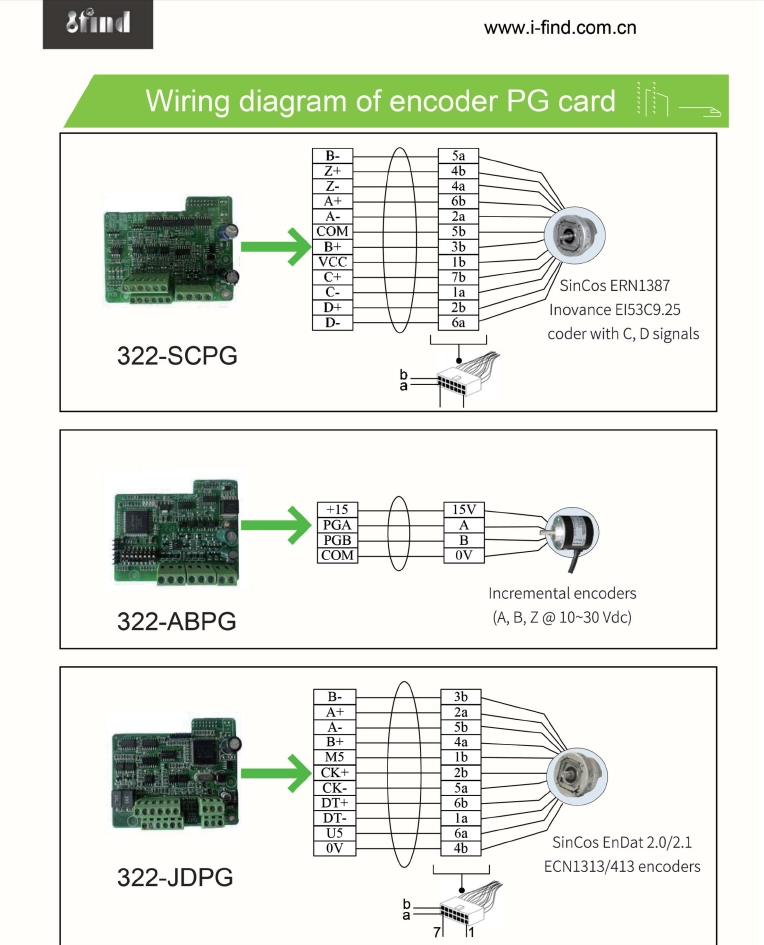

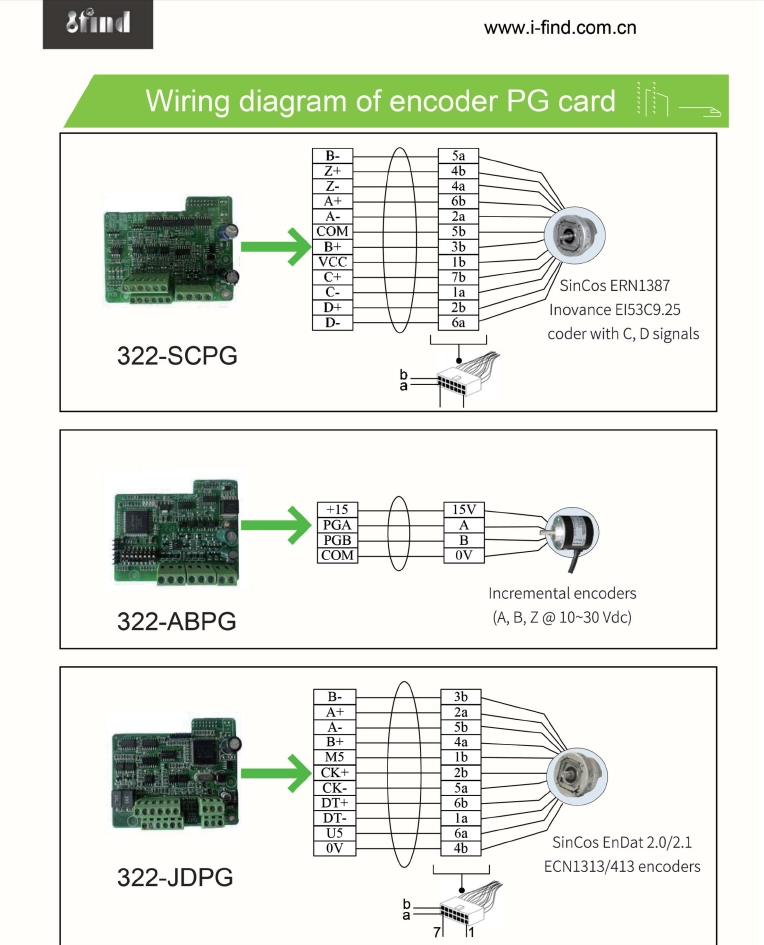

The 1387 requires a high-core-count cable (typically 14 cores). Each pair (A+/A-, B+/B-, C+/C-, D+/D-) must be strictly twisted and shielded. If a technician crosses the C and D wires, the motor will vibrate uncontrollably or run away.

The 1313 simplifies this. Because it uses serial communication (Clock and Data lines), the cable requires fewer conductors. This reduces the risk of wiring errors and makes the traveling cable thinner and more flexible.

Commutation Tuning (Encoder Alignment)

For any PMSM motor, the inverter must know the offset between the encoder's zero point and the motor's magnetic pole.

SD320L Solution: Our inverter features a Non-rotational Pole Position Identification algorithm. Whether you use a 1387 or 1313, you do not need to decouple the ropes from the sheave. The SD320L injects a high-frequency current to find the pole position, saving hours of labor.

Technical Comparison: 1387 vs. 1313

| Feature | Sin/Cos 1387 | EnDat 1313 |

| Interface Type | Analog (1Vpp) | Digital (EnDat 2.1/2.2) |

| Feedback Mode | Incremental + Commutation | Absolute |

| Startup Behavior | Requires initial pole-tuning | Instant position awareness |

| Noise Immunity | Moderate | High (Digital transmission) |

| Wiring Complexity | Higher (More cores needed) | Lower (Serial communication) |

| Cost | More Affordable | Premium / Higher Cost |

Why the IFIND SD320L is the Ideal Choice for Both Cards

Choosing the right encoder is only half the battle; you need an inverter capable of processing that data with industrial-grade reliability.

1. High-End Hardware Architecture

The IFIND SD320L does not compromise on components. We utilize:

Infineon/Fuji IGBTs: To ensure that the power delivered to the motor is as clean as the signal coming from the PG card.

Rubycon Capacitors: For a stable DC bus, which is essential for accurate PG card signal sampling.

2. Comprehensive Trip Diagnostics

Our PG cards are designed with self-diagnosis. If the 1387 signal amplitude drops (due to a worn encoder) or if the 1313 digital handshake fails, the SD320L provides a specific error code, allowing technicians to fix the issue in minutes rather than hours.

3. UPS and Emergency Rescue Support

Both our 1387 and 1313 interfaces are fully compatible with 220Vac UPS systems. In the event of a power failure, the SD320L uses the PG feedback to run the elevator in Light Load Direction, ensuring passengers are safely delivered to the nearest floor.

Strategic Recommendation: Which One Should You Buy?

Use Sin/Cos 1387 if:

You are modernizing an existing elevator that already has a 1387 encoder installed.

You are building standard residential elevators (1.0m/s - 1.75m/s) where budget efficiency is a priority.

Your technical team is already deeply familiar with analog tuning.

Use EnDat 1313 if:

You are working on high-speed projects (2.0m/s to 4.0m/s+).

The elevator is a heavy-duty cargo lift where maximum starting torque and zero-rollback are safety requirements.

You want the latest and greatest technology to reduce long-term maintenance visits.

Conclusion: Make the Industry Life Better

At Jiaxing IFIND Electromechanical Device Co., Ltd., we believe that the complexity of elevator technology should result in a simpler life for our customers. Whether you are an elevator manufacturer looking for a robust OEM inverter or a maintenance company looking to upgrade an old system, the SD320L with its versatile PG card options is designed to perform.

Understanding the difference between Sin/Cos 1387 and EnDat 1313 is the first step toward a superior elevator installation. The next step is choosing a partner who provides the technical support, hardware quality, and industry expertise to make your project a success.