Overview

The Open loop and close loop integrated elevator lift inverter represents a revolutionary advancement in elevator control technology. By seamlessly integrating the characteristics of both open - loop and closed - loop systems, this inverter offers a comprehensive and highly efficient solution for elevator operation.

Open - loop systems are known for their simplicity and cost - effectiveness, while closed - loop systems are prized for their high precision and feedback - based control. The integrated inverter combines these advantages, allowing it to adapt to different operating conditions and requirements. It is designed to work with a wide range of elevator motors and can handle various load capacities, making it suitable for installation in diverse buildings, from high - rise commercial complexes to residential apartments. With this integrated inverter, elevator systems can achieve enhanced performance, reliability, and energy efficiency.

Features

Dual - mode operation

The most prominent feature of this integrated inverter is its dual - mode operation. It can function in open - loop mode during normal, less - demanding operations, providing a simple and cost - effective control mechanism. When higher precision is required, such as during low - speed operations, accurate floor - leveling, or when carrying heavy and uneven loads, the inverter can seamlessly switch to closed - loop mode. In closed - loop mode, it uses feedback from sensors (such as encoder feedback for motor speed and position) to make real - time adjustments, ensuring extremely precise control over the elevator's movement.

High - precision control

In closed - loop mode, the inverter can achieve unparalleled precision in elevator control. It can accurately regulate the speed and torque of the elevator motor, reducing the margin of error in floor - leveling to a minimum. This precision not only enhances the comfort of passengers but also improves the safety of the elevator system. For example, it can ensure that the elevator stops exactly at the floor level, preventing any gaps or misalignments that could pose a tripping hazard.

Energy - saving capabilities

The integrated inverter is engineered with energy - saving in mind. It optimizes the power consumption of the elevator motor based on the actual load and operating conditions. In open - loop mode, it uses efficient control algorithms to minimize energy waste during normal operation. In closed - loop mode, by precisely adjusting the motor's output, it further reduces unnecessary energy consumption. Compared to traditional single - mode inverter systems, this integrated solution can achieve significant energy savings, contributing to lower operating costs for building owners and a reduced carbon footprint.

Fault - diagnosis and self - protection

Equipped with an advanced fault - diagnosis system, the inverter can quickly detect and identify various types of faults, such as over - voltage, under - voltage, over - current, and abnormal motor temperatures. Once a fault is detected, it immediately activates self - protection mechanisms to prevent damage to the inverter, motor, and other components of the elevator system. At the same time, it provides detailed fault information through its display or communication interface, facilitating quick troubleshooting and maintenance by technicians.

User - friendly interface and communication

The inverter features a user - friendly interface that allows operators and maintenance personnel to easily set parameters, monitor the elevator's operation status, and adjust the system settings. It also supports multiple communication protocols, such as Modbus, CAN, and Ethernet. This enables seamless integration with the building's overall elevator control system, as well as remote monitoring and management. Building managers can monitor the performance of the elevator inverter from a central control room or even remotely via the internet, ensuring timely maintenance and efficient operation.

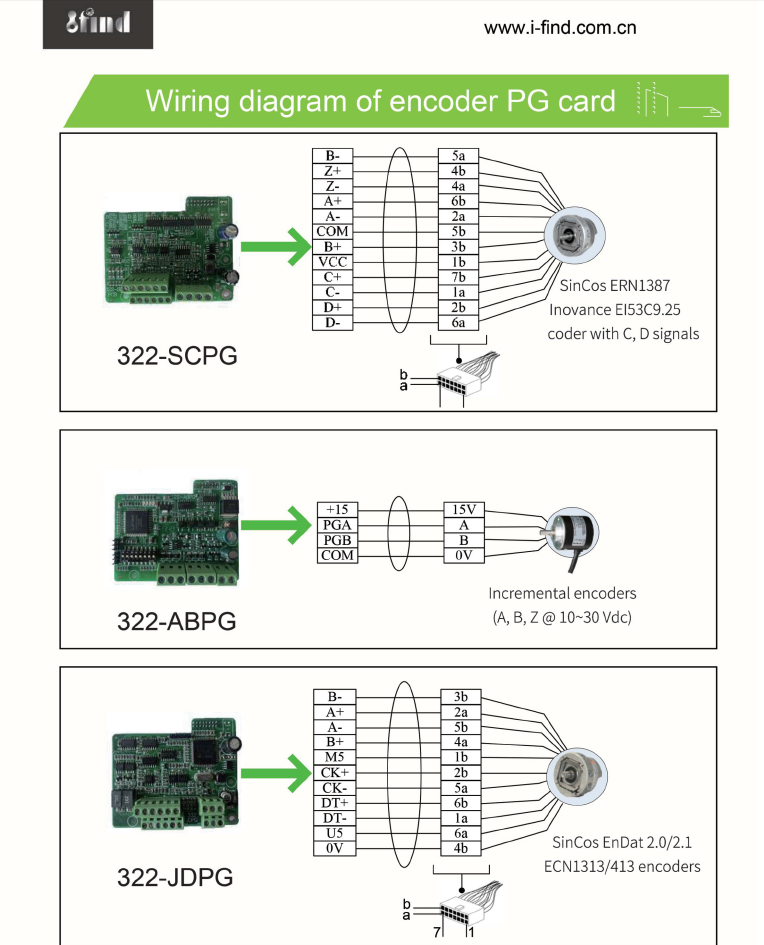

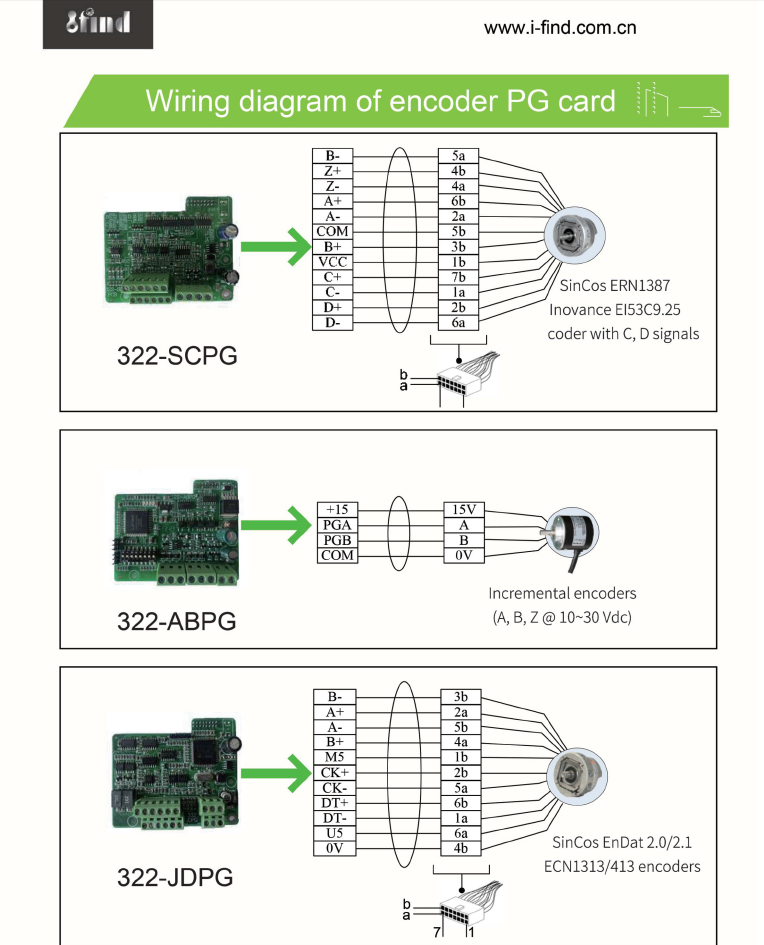

Drive both the asynchronous motor and permanent magnetic synchronous motor (PMSM), and provide multiple encoder interfaces

Support motor auto-tuning (static auto-tuning and complete auto-tuning)

Support multiple speed sources, multi-speed and analog setting

Guarantee good elevator riding comfort with flexible startup curves, multi-segment S-curve setting, and four groups of acceleration/deceleration time

Support emergency evacuation at power failure with the 48 V battery power supply

Provide various elevator-related functions, including enable detection, brake contactor control, output contactor control, slow-down judgment, overspeed protection, speed deviation detection, door preopen, contact stuck detection, motor overheat detection, and startup pre-torque compensation

Support connection to the external operation panel through the RJ45 interface, making the operation and commissioning simpler and easier

Provide the built-in DC reactor and braking unit, which improves the output power factor and reduces costs of peripheral devices

Separate air duct with conformal coating process, professional manufacturing platform, and advanced process make good product quality

Have the lightning protection design and the strong anti-interface capability, compliant with the EMC standard.

Support Synchronous and asynchronous motors

Suitable Heidenhain encoder. use 1387 PG card

Support industry UPS and home UPS

Open loop and close loop is integrated

Support gears and gearless motors

Applications

High - rise commercial buildings

In high - rise commercial buildings where elevators are in constant use and require high - speed operation and precise floor - leveling, the open - loop and closed - loop integrated inverter shines. It can handle the heavy traffic and diverse load conditions, ensuring that the elevators operate smoothly and efficiently, reducing waiting times for occupants and enhancing the overall experience of the building.

Luxury residential complexes

For luxury residential complexes, passenger comfort is of utmost importance. The high - precision control and smooth operation provided by the integrated inverter create a luxurious riding experience. The energy - saving features also appeal to environmentally - conscious residents and property managers, as it helps in reducing the building's energy bills.

Hospitals and medical facilities

In hospitals and medical facilities, where the transportation of patients, medical equipment, and supplies needs to be as smooth and safe as possible, the integrated inverter's precise control and reliability are essential. The ability to switch between open - loop and closed - loop modes allows for optimal performance under different circumstances, ensuring that the elevators can meet the demanding requirements of a medical environment.

Industrial buildings and warehouses

In industrial buildings and warehouses, where elevators are often used to transport heavy loads, the integrated inverter's dual - mode operation is highly beneficial. In open - loop mode, it can handle normal material handling operations efficiently, while in closed - loop mode, it can provide the necessary precision for tasks such as accurately positioning heavy machinery or equipment on specific floors.

| IGBT | STARPOWER/ INFINEON/FUJI |

| FAN | PELKO/NIDEC |

| CAPACITORS | RUBYCON/JIANGHAI |

| ELECTRONIC | DELTA |

Voltage class | 220VAC | 380 to 480AC |

Drive Model | SD320L 3.7KW-2 | SD320L 5.5KW-2 | SD320L 7.5KW-2 | SD320L 3.7KW-4 | SD320L 5.5KW-4 | SD320L 7.5KW-4 | SD320L 11KW-4 | SD320L 15KW-4 |

Dimension | Height Width Depth | [H]:250mm [W]:160mm [D]:183mm | [H]:320mm [W]:220mm [D]:183mm | [H]:250mm [W]:160mm [D]:183mm | [H]:320mm [W]:220mm [D]:183mm |

Mounting Hole | Ф5 | Ф6 | Ф5 | Ф6 |

Drive Input | Rated Input Voltage | Three-phase 200Vac to 240Vac,-15% to +10% (170Vac to 264Vac) | Three-phase 380Vac to480Vac,-15% to +10% (323Vac to 528Vac) |

Rated Input Current,[A] | 10.5 | 14.6 | 26 | 35 | 10.5 | 14.8 | 20.5 | 29 | 36 |

Rated Input Frequency | 50/60Hz,±5%(47.5 to 63Hz) |

Drive Output | Applicable Motor | [kW] | 2.2 | 3.7 | 5.5 | 7.5 | 3.7 | 5.5 | 7.5 | 11 | 15 |

[HP] | 3 | 5 | 7.5 | 10 | 5 | 7.5 | 10 | 15 | 20 |

Output Current,[A]*1 | 9 | 13 | 25 | 32 | 9 | 13 | 18 | 27 | 33 |

Power Capacity,[kVA] | 5.9 | 8.9 | 17 | 21 | 5.9 | 8.9 | 11 | 17 | 21 |

Overload Capacity | 150% for 60 Sec &180% for 3 Sec |

Max. output voltage | Three-phase 200Vac to 240Vac (Proportional to input voltage) | Three-phase 380Vac to 480Vac (Proportional to input voltage) |

Max. output frequency | 100 Hz |

Braking Resistor | Recommended power,[W] | 500 | 750 | 1200 | 1500 | 750 | 1200 | 1500 | 2500 | 3000 |

Recommended Resistance,[Ω] | ≥65 | ≥45 | ≥22 | ≥16 | ≥130 | ≥90 | ≥65 | ≥43 | ≥32 |

| Enclosure | IP 21 |